Paperless Working Part 1 - GoodNotes

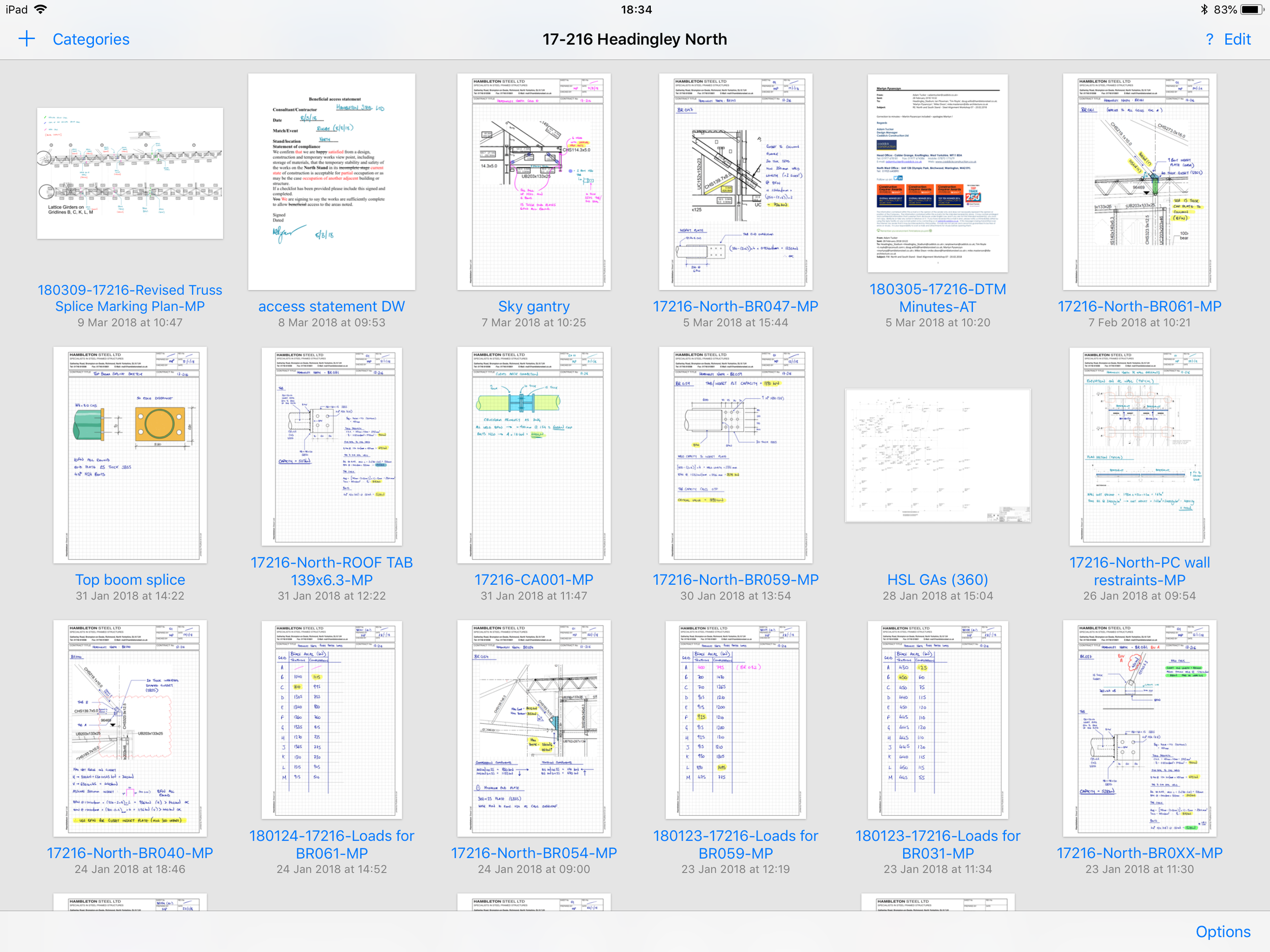

If you were to take a look at my iPad when I’m working I can safely estimate a 90% chance you’d see it running GoodNotes. Everything I would have previously done on paper, is now done on my iPad Pro 12.9” via GoodNotes with the Apple Pencil.

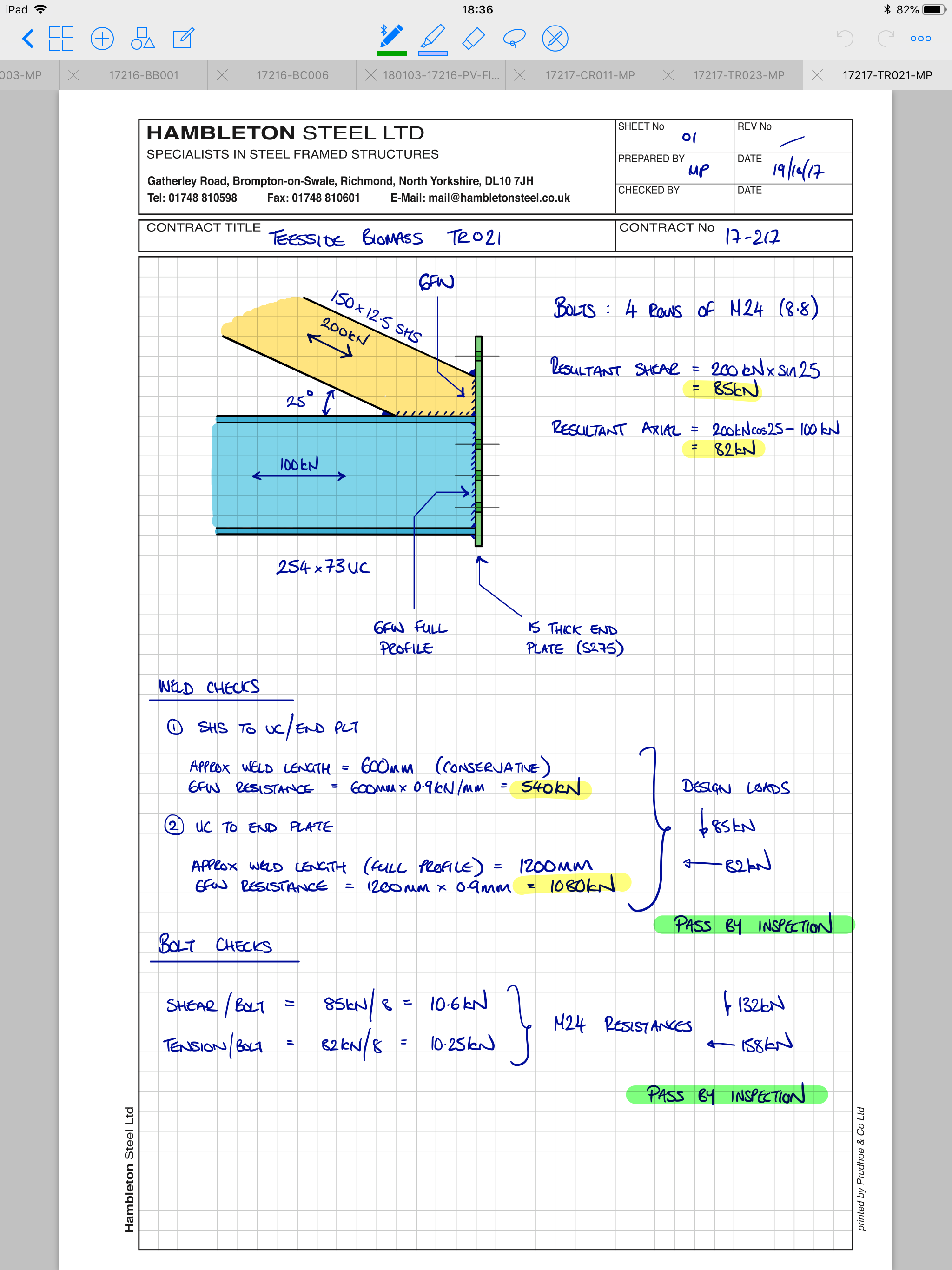

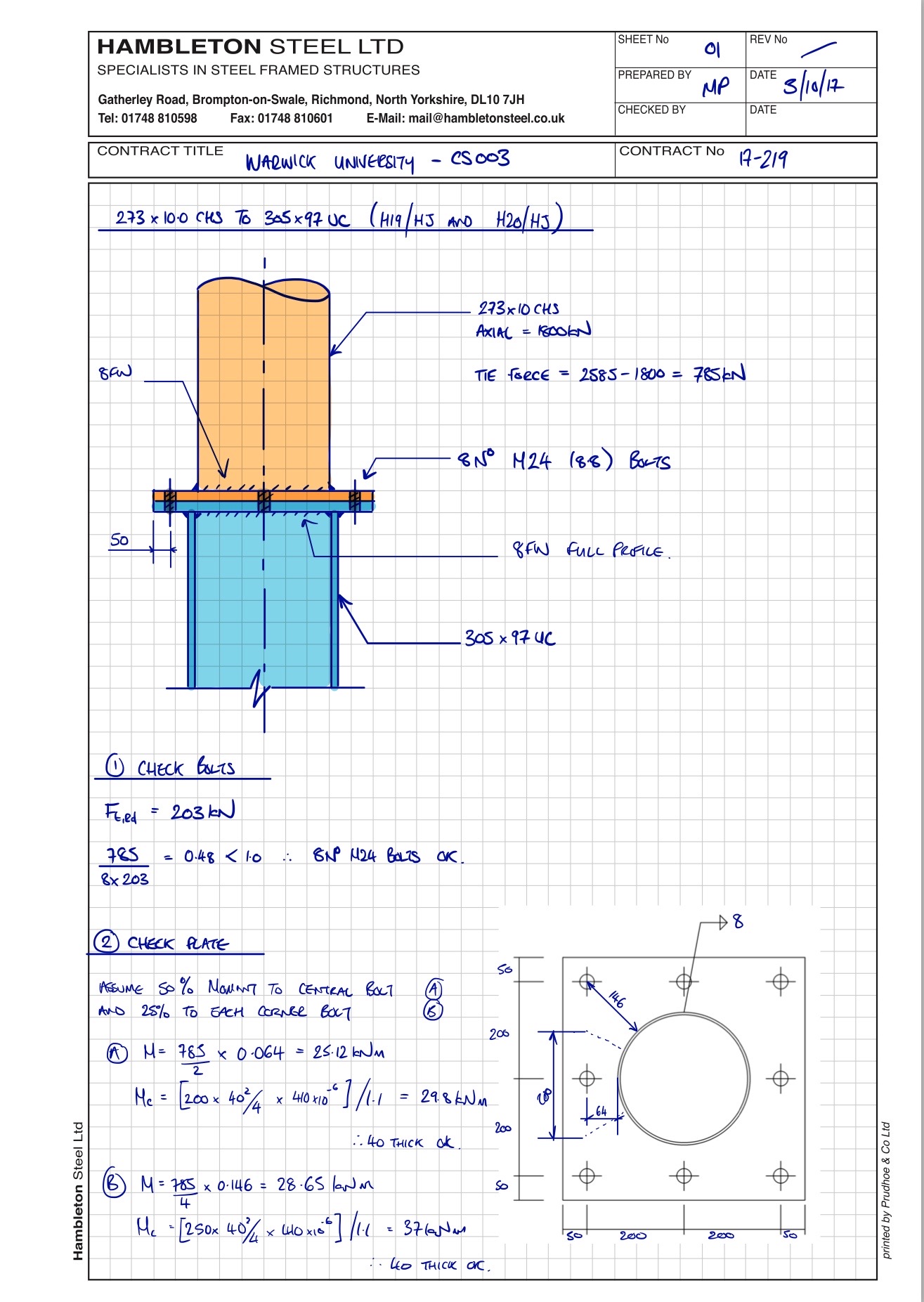

- Hand calculations: GoodNotes

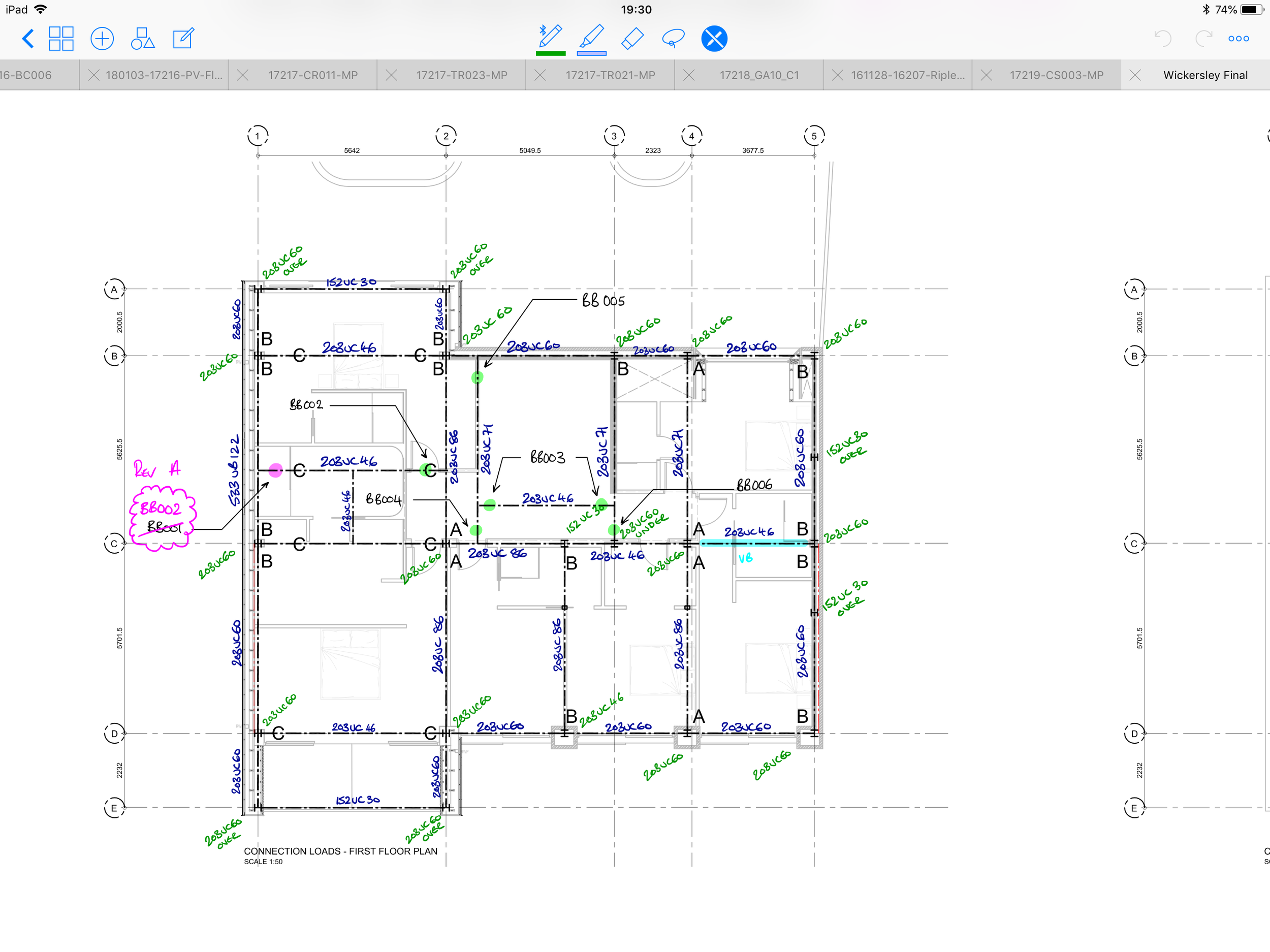

- Marking up drawings: GoodNotes

- Any sort of document that requires my signature: GoodNotes

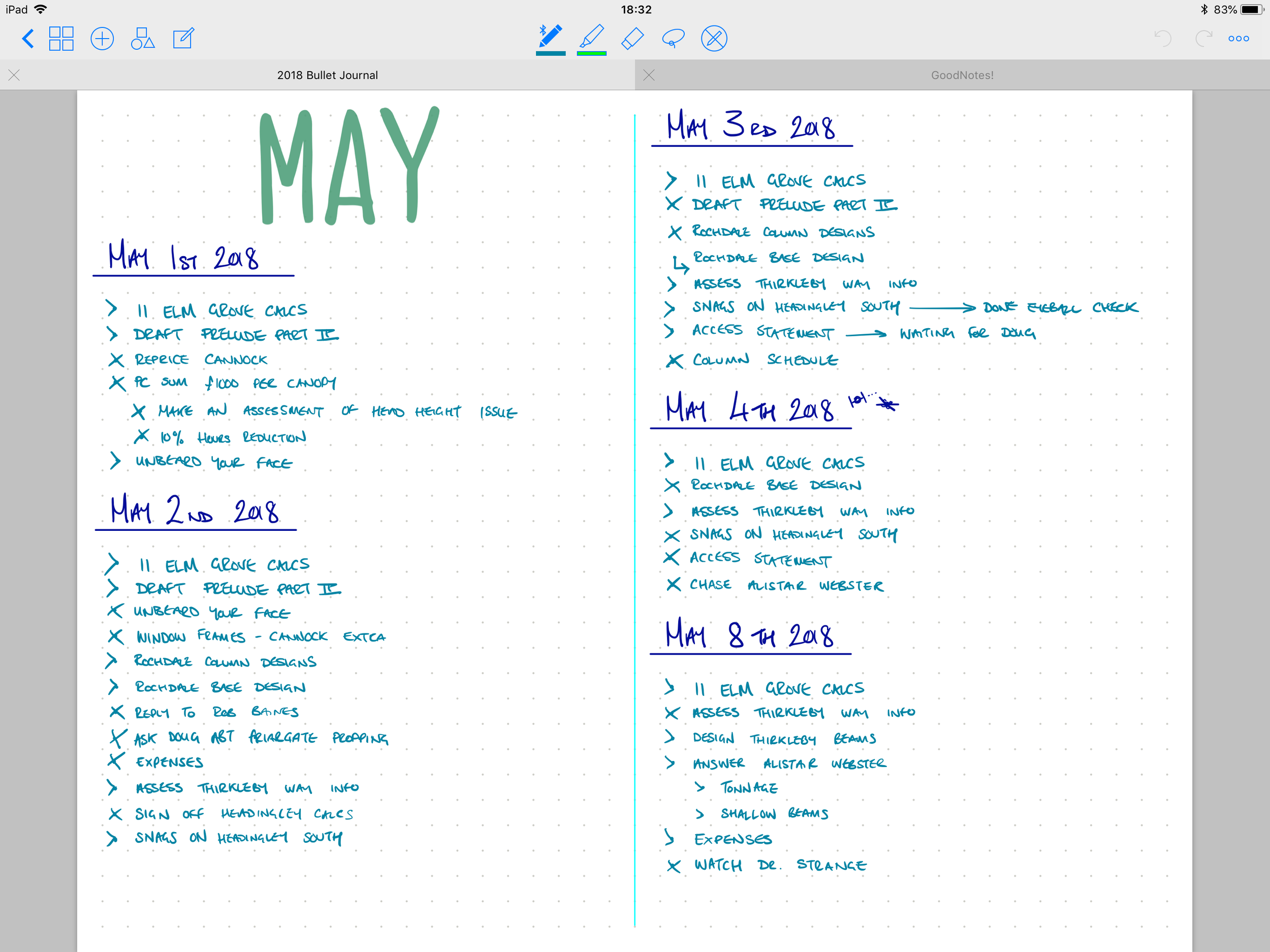

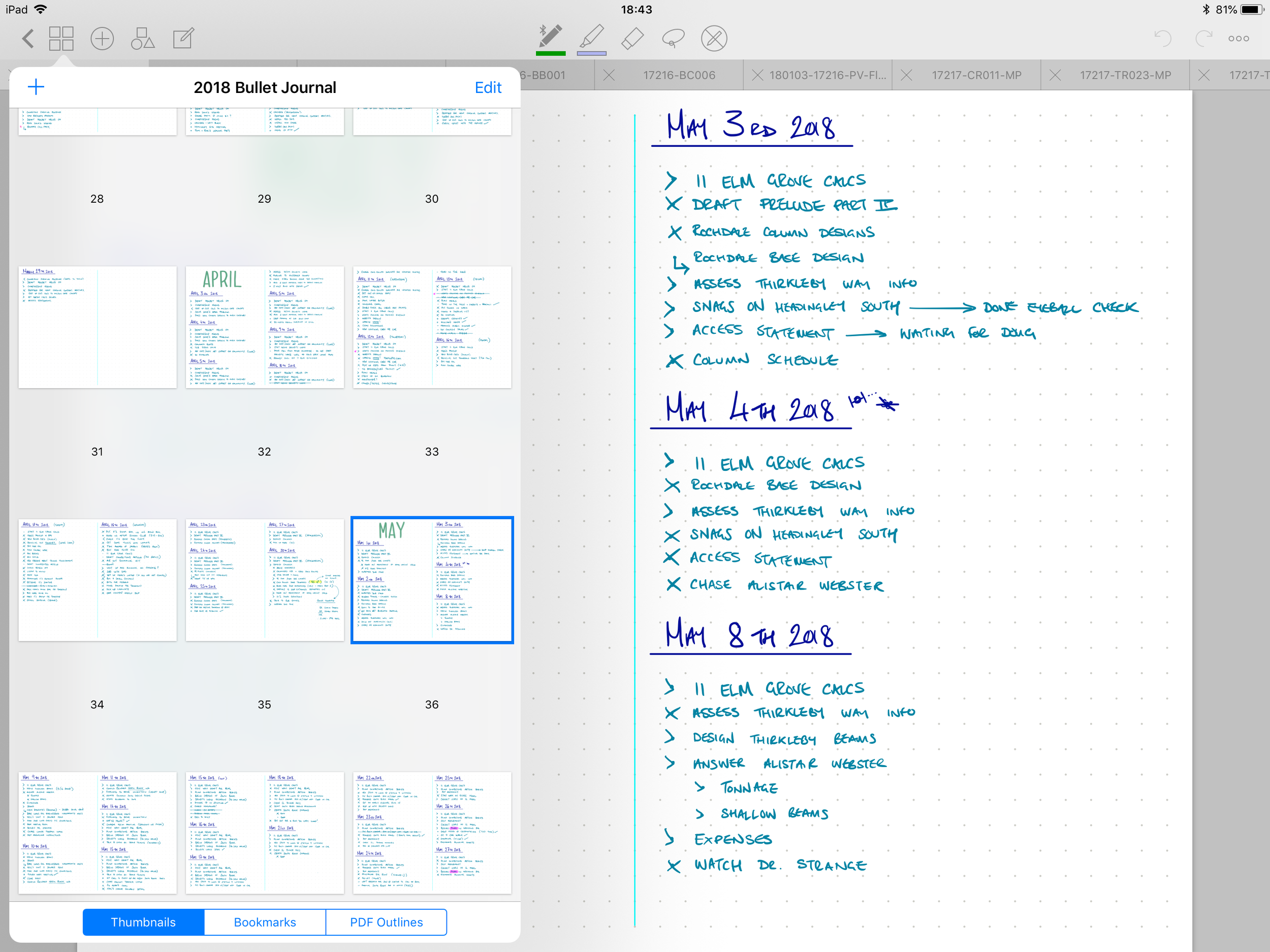

- To-do list: GoodNotes

- Specification documents needing to be reviewed: GoodNotes

Note: clicking on an image in the gallery moves to the next image.

And the list goes on.

GoodNotes is at its core a vector based PDF markup tool with a small but near perfect box of tools. The most notable feature is the very best digital handwriting inking engine I’ve seen on iOS - and I have tried a lot of handwriting apps. The talented people who made and maintain GoodNotes market it heavily to students as a note-taking tool, and with good reason - it is truly wonderful for note-taking. The great news for engineers is that the features included and the design decisions made for GoodNotes make it an incredible paper replacement for the practicing structural engineer.

Before we talk about why GoodNotes is great for engineers, let’s cover the basics: Any handwriting app worthy of notice should feel great to write on, and produce handwriting that is unmistakably that of the writer. GoodNotes does this splendidly. The act of writing feels natural, and the results, at least to my eye, are perfect. Also notable: the palm rejection with the Apple Pencil is great.

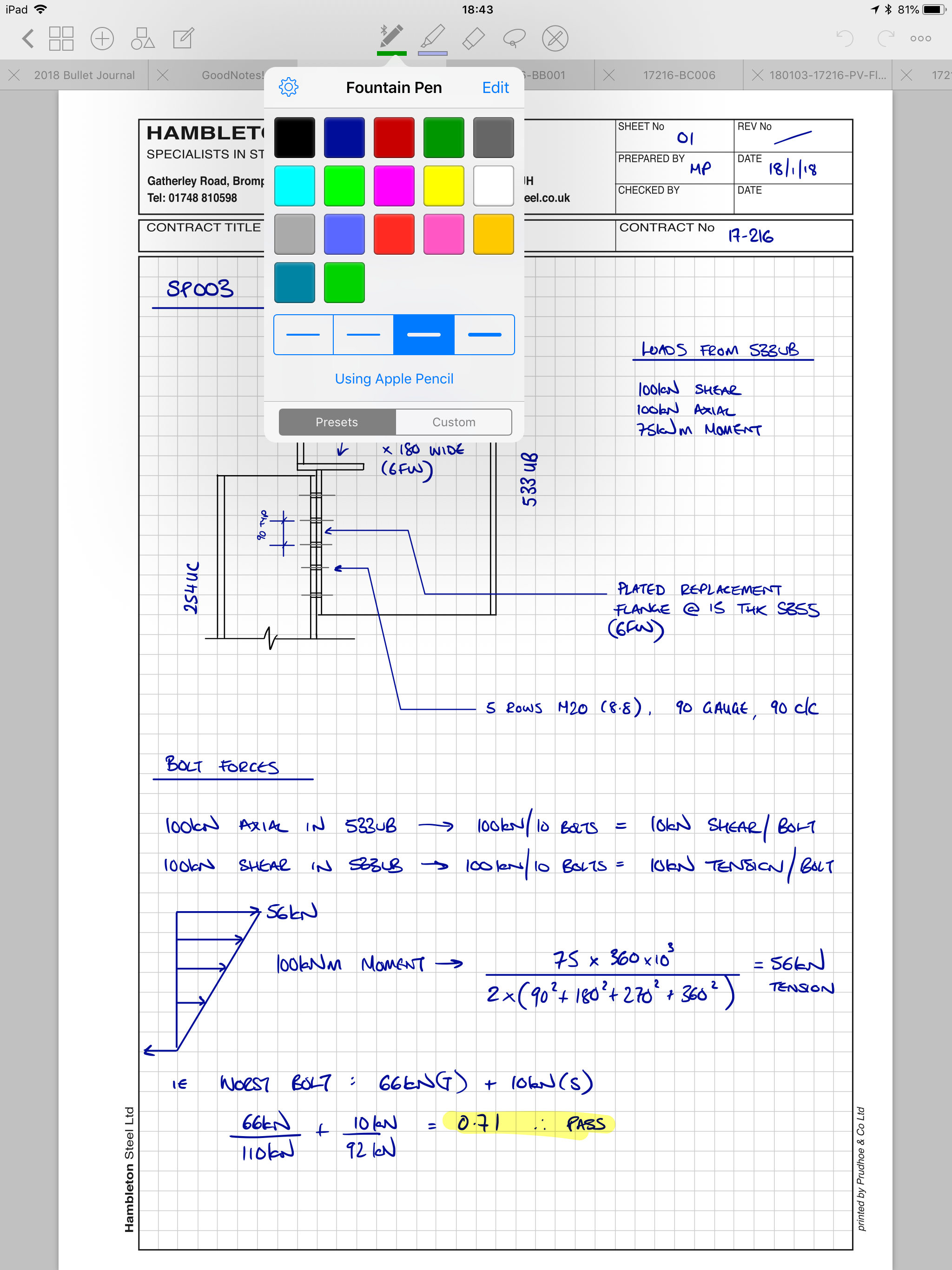

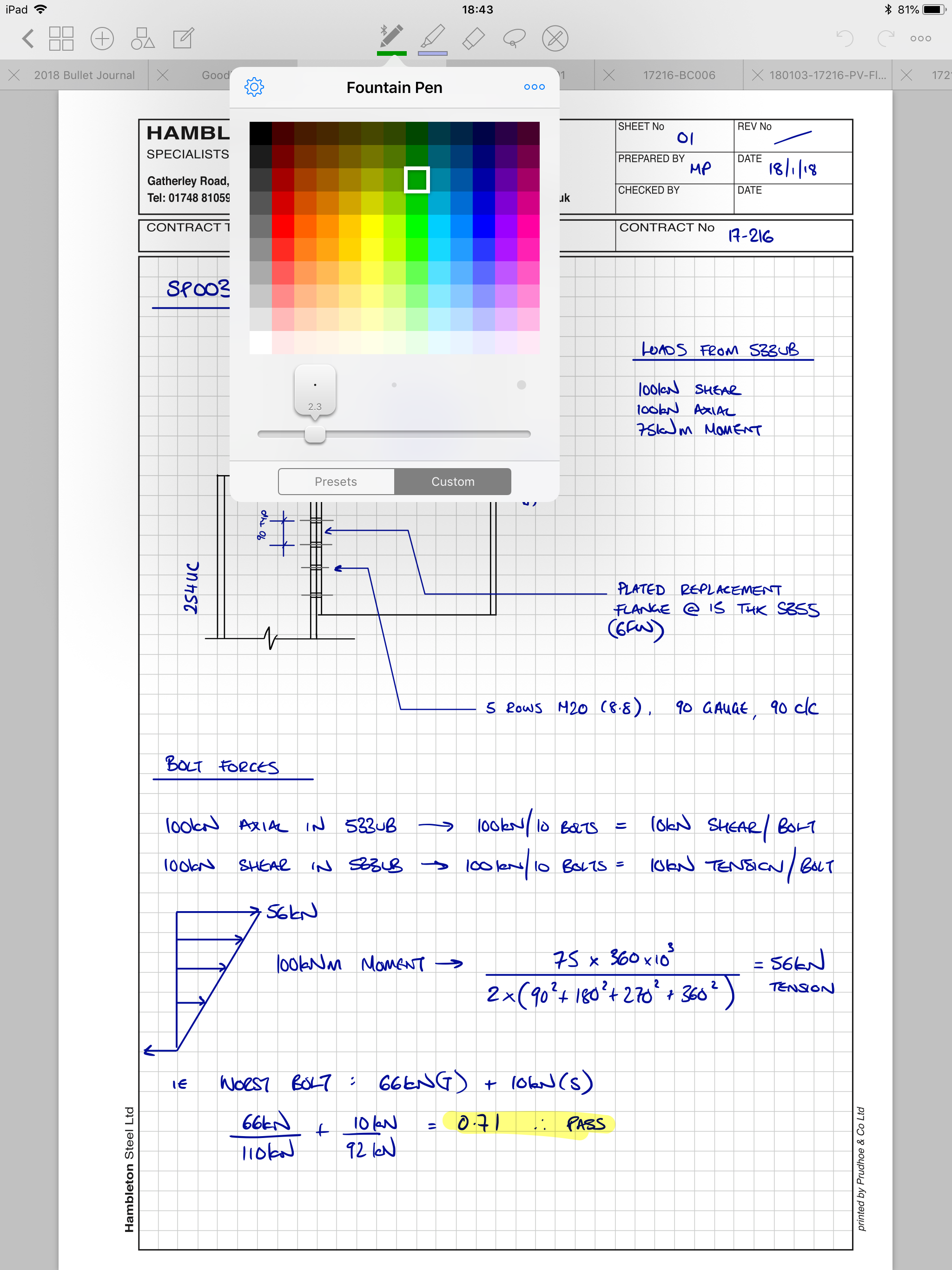

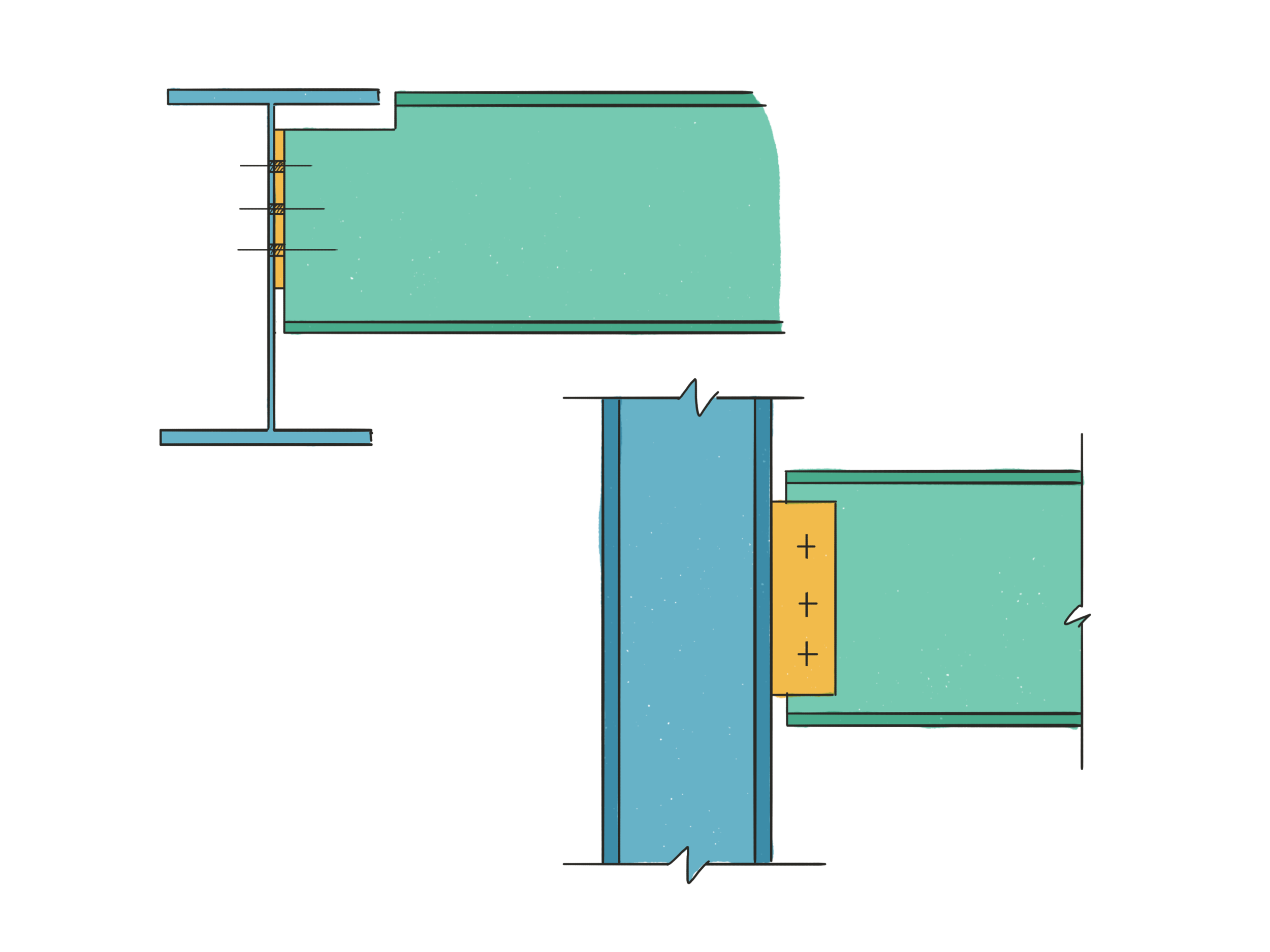

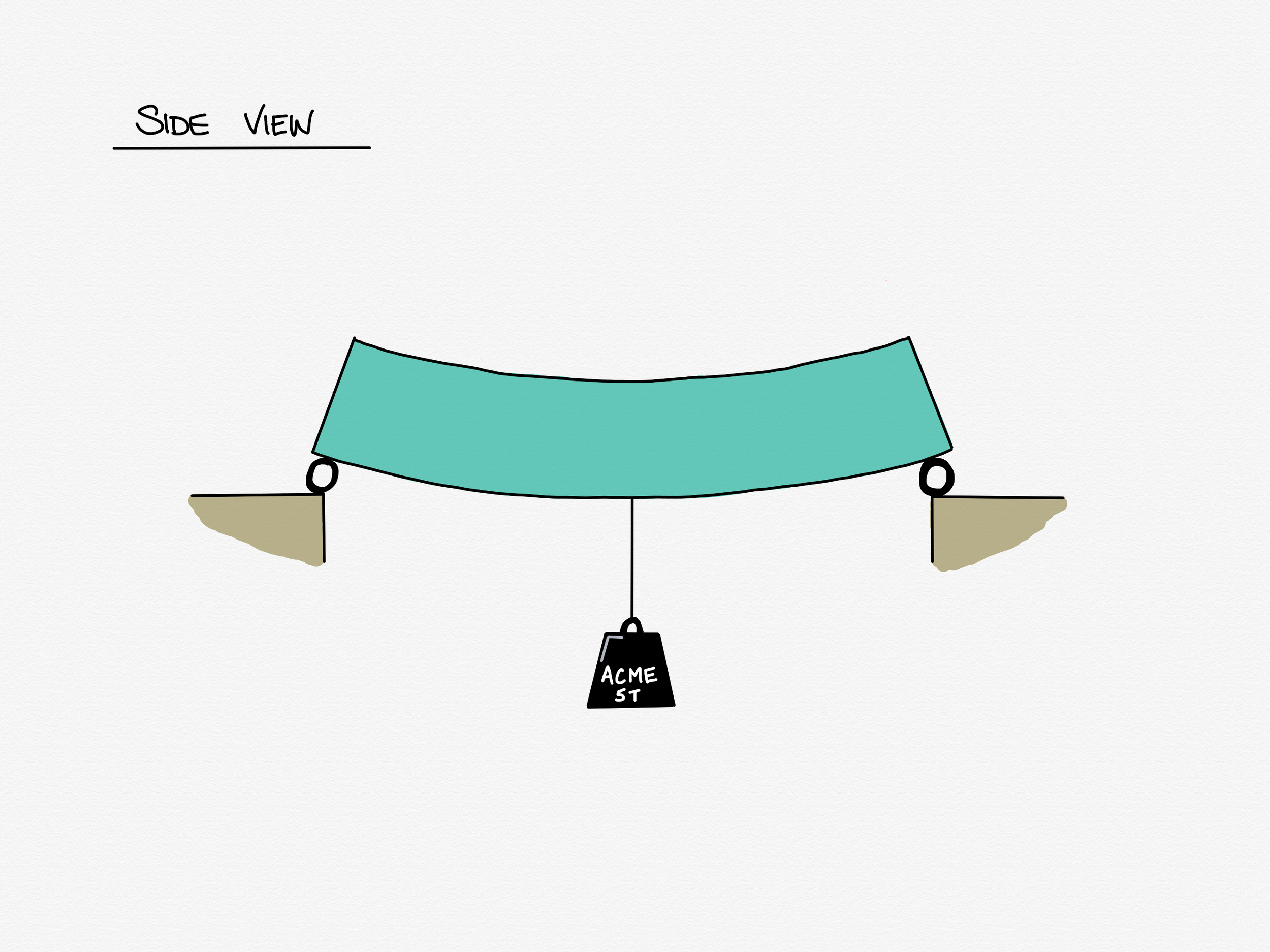

The pen tool can be switched from a fountain pen feel to a ball-point pen feel, and there are 15 preset colours to choose from. You have the option of expanding your default palette from a grid of 150-odd more, or the freedom to feed it hex codes for any colour you wish. There are 4 preset stroke widths to pick with, but they can also be adjusted with a custom slider. I’ve tweaked my stroke widths slightly and added two shades of green to my palette, but otherwise tend to stick to the defaults. My go-to colours in the fountain pen are the default deep blue, and a teal that I took from the expanded colour picker.

The highlighter tool has the same colour and stroke width customisability, and the transparency allows you to layer colours up too, should that take your fancy.

Aside from the excellent pen, there are tonnes of features that make GoodNotes ideal for engineers. You can:

- Import PDFs as templates into the app’s library. This is where I keep a copy of our company’s calc paper. New page creation is an absolute doddle when you are working too. To create a new blank page, you simply swipe past your final page and GoodNotes will insert a new page using the template you’re currently working on.

- Import PDFs as standalone documents (from Dropbox or similar), or import them as new pages in an existing document. Want to import a set of architect’s drawings? No problem - you can decide either to import them as individual files (which you can view in separate tabs), or you can import them a single batch so each drawing is in one multi-page document with each drawing on a separate page.

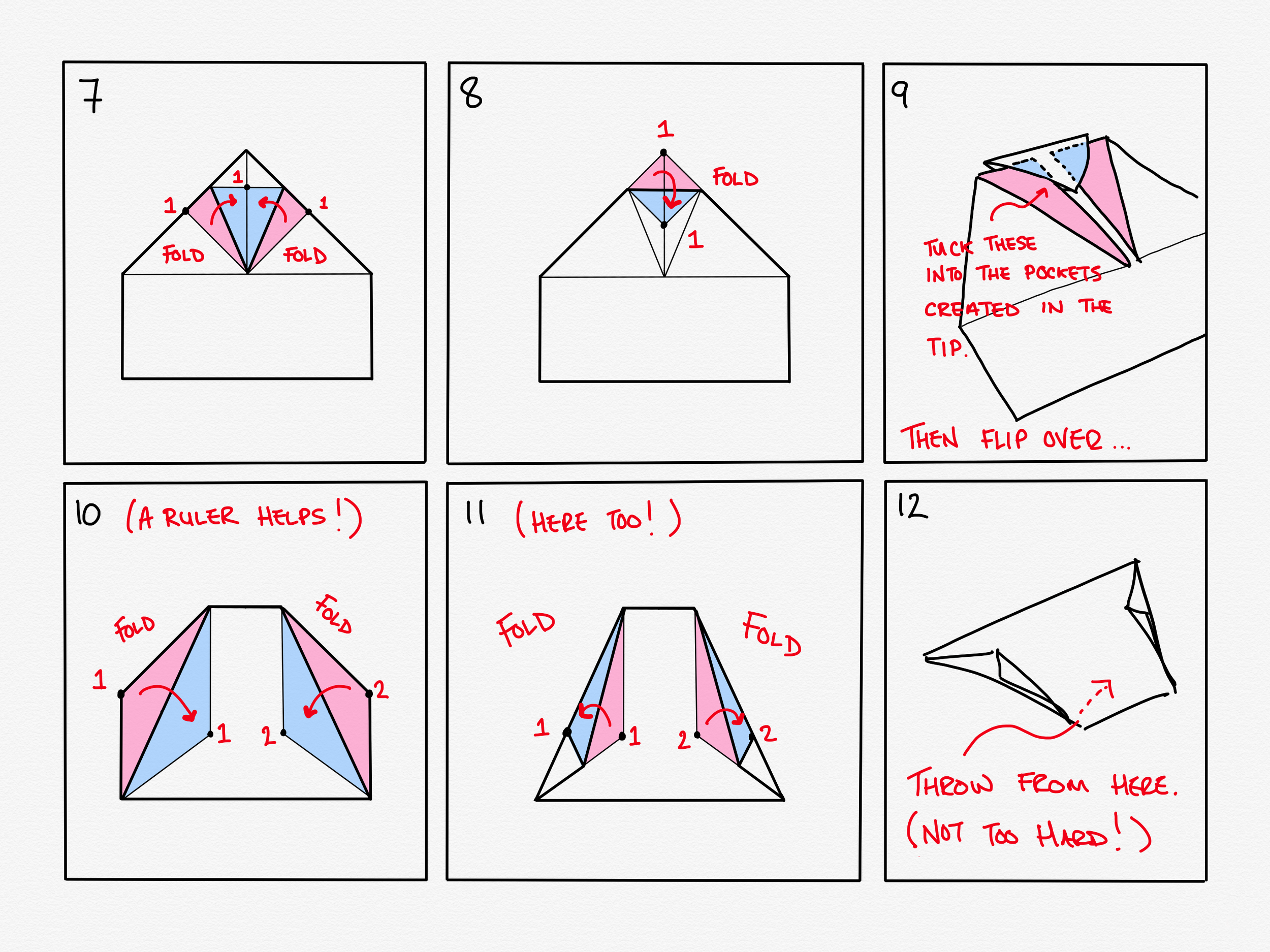

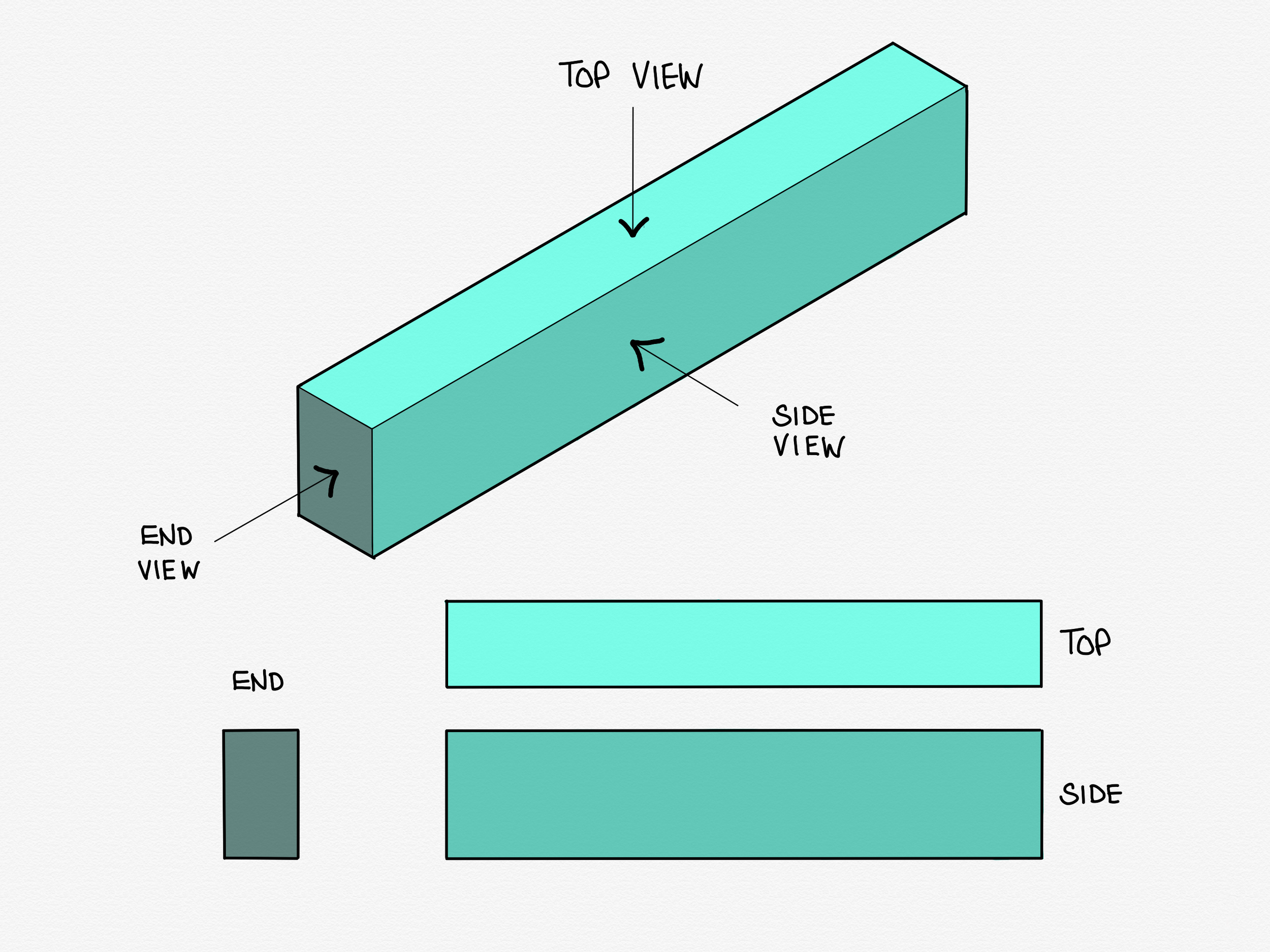

- Draw straight lines and a few basic shapes with either the pen tool or the highlighter tool with a toggle. This is extremely useful for doing small sketches within your calcs, or neat dimension lines or leaders.

- Use a lasso tool to select and move or copy any marks you’ve made. This is very helpful for sketches, and little things like copying titles across calc pages as well as just making everything line up nicely after you’ve done it. The lasso can be toggled to select any or all of handwriting marks, imported images, and text boxes. This is such a useful touch - if you’ve imported a snapshot of a drawing or design model and marked it up you can still tweak your marks without also moving the import underneath.

- Search within your notes for text including your handwritten notes. The OCR is pretty damn accurate.

- Insert images and text, rearrange your pages and all the other myriad basics you’d expect. Especially handy is support for transparent PNG files, which allows seamless import of more complex sketches done in other apps.

- Switch the eraser tool from traditional to erase entire stroke. This is incredibly useful for correcting dense calcs. Also very handy if you want to draw some guidelines for writing, then erase them after.

- iCloud sync means that everything on my iPad is also available on my phone. I personally don’t use the phone version for creating anything, but having access to absolutely everything I’ve ever written all of the time in my pocket has saved me on a good few occasions.

Before I wrap up, it’s only fair I mention the few things that could be improved, particularly from the point of view of an engineer. I realise my wish list is both rather selfish and not necessarily aimed at the core market of the app, but I’d like to hope that improvements that fix the issues I have highlighted below will benefit all users... So, here goes:

- Selected items cannot be scaled or rotated. This is a feature available in GoodNotes’ closest competitor, Notability, and I suspect is one the developers are actively working on.

- Whilst realising GoodNotes is a handwriting app first and foremost, the limitations placed on sketching are sometimes a drawback. For example, the straight line detection will snap lines drawn at shallow angles to be horizontal. A ruler tool like the one included in the Apple Notes app would be wonderful. Better yet if it could at least report the angle to the horizontal and better still if the user could define an angle to set it at.

- If I’m being really cheeky, a straight up copy of Adobe Sketch’s French Curve tool would be lovely.

- GoodNotes lacks a fill tool. A good deal of my time when sketching in GoodNotes is spent oh-so-carefully trying to use a highlighter with a circular tip filling in shapes with defined square edges without going over the lines OR taking the pencil off the screen. If you do either you have to start again if you want a neat block of uniform colour.

- Bookmarks added to GoodNotes do not export back out to PDF. I believe this is also on the to-do list of the developers though.

- Really getting nitpicky now: the default action when importing multiple items is to import them all as separate documents within GoodNotes. Getting them into a single document is a manual if fairly quick and simple process, but it would be lovely if the app were to ask if you want one document or multiple at point of import.

To summarise:

For the practicing engineer GoodNotes has almost everything you need to replace paper. Since getting my iPad Pro and GoodNotes about a 2 years ago I have not used a single sheet of calc paper. I still hop out of GoodNotes to create complex sketches in either Linea Sketch or Paper by 53 depending on the style I’m going for. Both of these apps are able to export transparent PNGs to import back into GoodNotes, blending them seamlessly into your calcs.

Given that GoodNotes is primarily a note-taking app, I can absolutely forgive it for not catering to my entire fantasy wishlist of features, and declare it truly and honestly to be the number one app on my iPad, head and shoulders above everything else.

GoodNotes, I salute you.